The 3D Innovation Lab of Humanitas University obtained ISO 13485 certification, which defines the requirements for quality management systems applied to medical devices according to international standards. “Thanks to this important milestone, Humanitas University is now the first University in Italy registered with the Ministry of Health as a manufacturer of custom-made medical devices produced through 3D printing” – states Luigi Maria Terracciano, Rector of Humanitas University and Scientific Director of Humanitas Research Hospital, “operating in full compliance with the highest safety and quality requirements established by the European MDR Regulation 2017/745.”

Innovation and research at the service of patient care

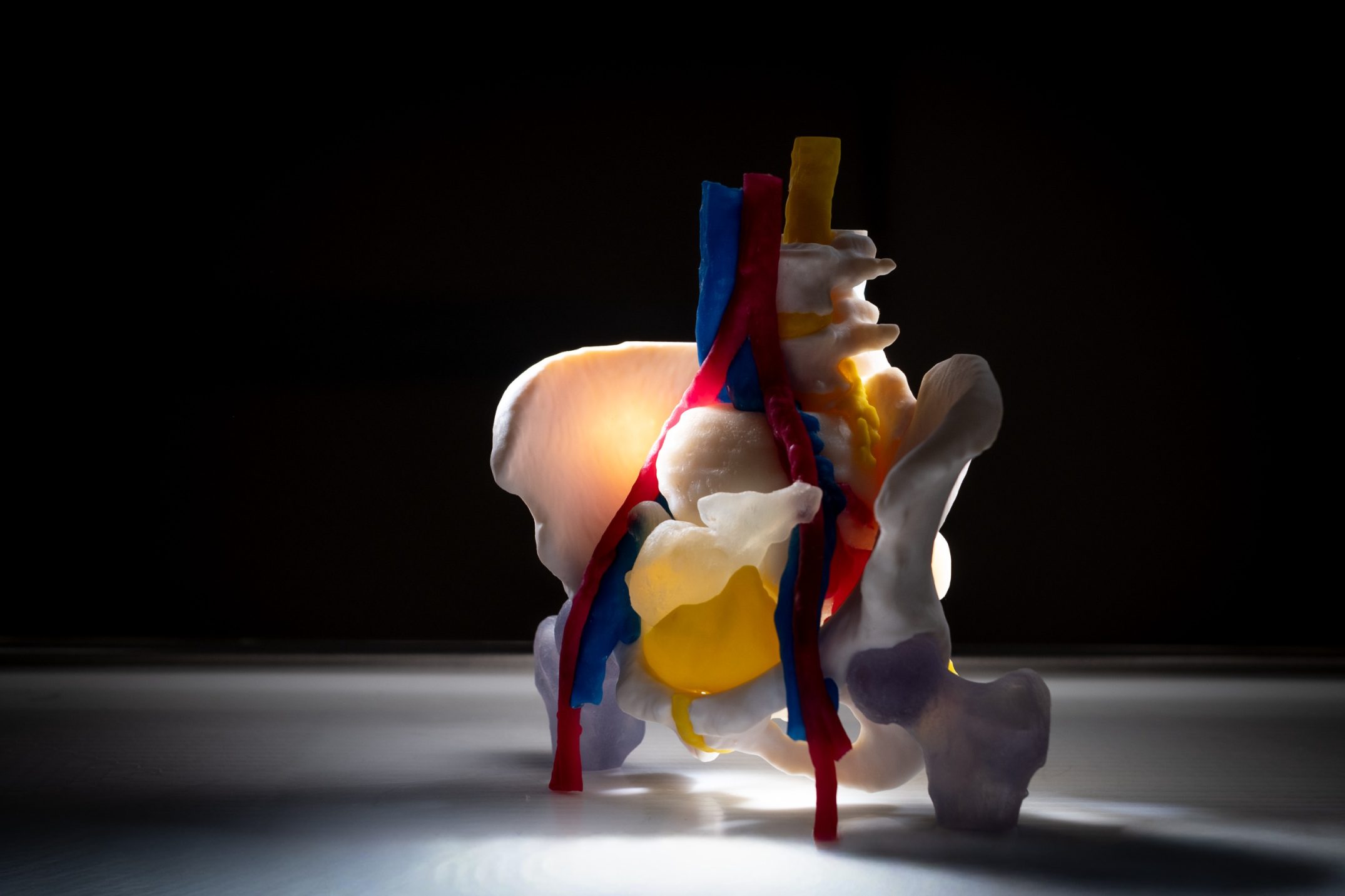

Surgery is evolving toward increasingly personalized procedures, literally designed around the patient’s physical anatomy and the specific manifestation of their disease: whether it involves the removal of tumoral tissue from the liver or the heart, or the planning of complex procedures never before undertaken by a surgical team, the ability to produce devices through 3D printing that faithfully reproduce organs – respecting dimensions, morphology, and mechanical properties – is becoming a fundamental ally for clinicians.

In this context, with ISO 13485 certification, the 3D printing laboratory team will be able to operate as a manufacturer of custom-made medical devices produced through additive technologies, i.e., processes that build objects layer by layer. This evolution will make it possible to produce personalized solutions to support, among other things, surgical planning and execution, thereby expanding the clinical and scientific impact of the laboratory’s activities.

“The certification consolidates our role as a hub for the production of patient-specific medical devices and represents a fundamental step toward increasingly personalized medicine, in which technology is concretely placed at the service of each patient,” explains Paolo Oliva, Head of the 3D Innovation Lab. “An additional added value is the ability to produce devices (specifically anatomical models and surgical guides) that are sterilizable and ready for use in the operating room, guaranteeing the highest safety standards.”

A new model for personalised medicine

With ISO 13485 certification, Humanitas University will be able to launch a new line of activities, producing personalized devices also at an international level.

To support the production process, the laboratory is developing a dedicated digital platform that will allow physicians to request customized models and surgical guides in a safe, traceable, and GDPR-compliant manner. The system will offer a fast, reliable, and accessible service, combining in-house medical know-how with the safety of certified materials.

Thanks to this platform, close collaboration between engineers and clinicians becomes even more effective: surgeons’ needs are translated into precise and immediately applicable technical solutions, integrating technology, medical expertise, and innovation into a single operational workflow.

The strength of integration between research and innovation

The ability to design and produce custom-made devices further strengthens Humanitas University’s role as a hub of technological innovation in the field of medical education and translational research. The 3D Innovation Lab thus continues its mission of integrating technological innovation, research, and education, contributing to the development of a healthcare system that is more effective, precise, and person-centered.

“This certification represents a fundamental milestone for our University: it is concrete proof of how interdisciplinarity – which we teach our students every day and which guides our educational vision – can translate into a useful, high-impact service for society. Creating collaboration among engineers, physicians, researchers, and healthcare professionals not only raises the quality of innovation, but also offers solutions that improve patient care and quality of life. This is the deepest value of our mission,” concludes Luigi Maria Terracciano.